Heavy Duty Face Mount Joist Hangers – NVFH

| Product Code |

W in |

H in |

No. of Joist | Joist Size |

| NVGH 26 | 1 9⁄16 | 3 ½ | 1 | 2×4 – 2×6 |

| NVGH 28 | 1 9⁄16 | 5 ½ | 1 | 2×6 – 2×8 |

| NVGH 210 | 1 9⁄16 | 7 ½ | 1 | 2×8 – 2×10 |

| NVGH 212 | 1 9⁄16 | 9 ½ | 1 | 2×10 – 2×12 |

| NVGH 26-2 | 1 9⁄16 | 11 ½ | 1 | 2×12 – 2×14 – 2×16 |

| NVGH 28-2 | 3 1⁄8 | 3 ½ | 2 | 2×4 – 2×6 |

| NVGH 210-2 | 3 1⁄8 | 5 ½ | 2 | 2×6 – 2×8 |

| NVGH 212-2 | 3 1⁄8 | 7 ½ | 2 | 2×8 – 2×10 |

| NVGH 36 | 3 1⁄8 | 9 ½ | 2 | 2×10 – 2×12 |

| NVGH 38 | 3 1⁄8 | 11 ½ | 2 | 2×12 – 2×14 – 2×16 |

| NVGH 310 | 2 9⁄16 | 5 ½ | 1 | 3×6 3×8 |

| NVGH 312 | 2 9⁄16 | 7 ½ | 1 | 3×8 3×10 |

| NVGH 36-2 | 2 9⁄16 | 9 ½ | 1 | 3×10 3×12 |

| NVGH 38-2 | 2 9⁄16 | 11 ½ | 1 | 3×12 3×14 3×16 |

| NVGH 310-2 | 5 1⁄8 | 5 ½ | 2 | 3×6 3×8 |

| NVGH 312-2 | 5 1⁄8 | 7 ½ | 2 | 3×8 3×10 |

| NVGH 26-3 | 5 1⁄8 | 9 ½ | 2 | 3×10 3×12 |

| NVGH 28-3 | 5 1⁄8 | 11 ½ | 2 | 3×12 3×14 3×16 |

| NVGH 210-3 | 4 5⁄8 | 5 ½ | 3 | 2×6 2×8 |

| NVGH 212-3 | 4 5⁄8 | 7 ½ | 3 | 2×8 2×10 |

| NVGH 28-4 | 4 5⁄8 | 9 ½ | 3 | 2×10 2×12 |

| NVGH 210-4 | 4 5⁄8 | 11 ½ | 3 | 2×12 2×14 2×16 |

| NVGH 212-4 | 6 1⁄8 | 7 ½ | 4 | 2×8 2×10 |

| NVGH 46 | 6 1⁄8 | 9 ½ | 4 | 2×10 2×12 |

| NVGH 48 | 6 1⁄8 | 11 ½ | 4 | 2×12 2×14 2×16 |

| NVGH 410 | 3 9⁄16 | 3½ | 1 | 4×4 4×6 |

| NVGH 412 | 3 9⁄16 | 5 ½ | 1 | 4×6 4×8 |

| NVGH 66 | 3 9⁄16 | 7½ | 1 | 4×8 4×10 |

| NVGH 68 | 3 9⁄16 | 9½ | 1 | 4×10 4×12 |

| NVGH 610 | 3 9⁄16 | 11½ | 1 | 4×12 4×14 4×16 |

| NVGH 612 | 5½ | 5 ½ | 1 | 6×6 6×8 |

| NVGH 86 | 5½ | 7½ | 1 | 6×8 6×10 |

| NVGH 88 | 5½ | 9½ | 1 | 6×10 6×12 |

| NVGH 810 | 5½ | 11½ | 1 | 6×12 6×14 6×16 |

| NVFH 86 | 7½ | 5 ½ | 1 | 8×6 8×8 |

| NVFH 88 | 7½ | 7½ | 1 | 8×8 8×10 |

| NVFH 810 | 7½ | 9½ | 1 | 8×10 8×12 |

| NVFH 812 | 7½ | 11½ | 1 | 8×12 8×14 8×16 |

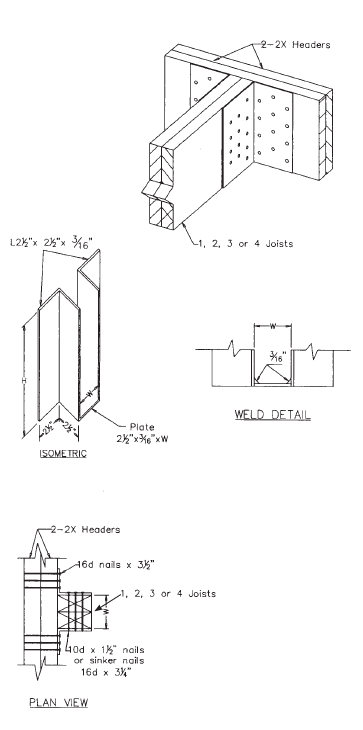

Structural Notes:

1) For one or two joists side by side, use 10dx1 1/2” nails from each side. For 3 Joists side by side, use 16dx3 1/4” sinker nails fron one side and 10dx1 1/2” nails from opposite side. For 4 Joists, used 16d sinker nails from each side.

2) Use hanger capacity or shear capacity whichever is less. Joist Shear capacity shown * exceeds hanger capacity. For these joists use hanger capacity.

3) All design conforms to FBC 2014, IBC/IRC 2015/2012 and NDS 2012.

4) Structural steel shall conform to ASTM A36, yield strength 36000 psi.

5) All welding shall be minimum 3/16˝ with E70 electrodes and shall conform to latest AISC/AWS codes. All welds shall be fillet welds.

6) All nail values in wood conform to latest Edition of NDS for Southern Pine, G=0.55. Values for other species shall be adjusted as per NDS. This applies also to shear values of joists.

7) Steel stress is not increased by 33%.

8) Provide plywood shims to close the gap between joist and steel hangers to prevent bending if necessary.

9) All products are painted Royal Blue for easy identification

| Joist Size | Fv=175 psi Shear Capacity (Lbs.)(2)(6) | |

| Uplift 160% | Gravity 100% | |

| 2×4 | 980 | 615 |

| 2×6 | 1540 | 960 |

| 2×8 | 2030 | 1270 |

| 2×10 | 2590 | 1620 |

| 2×12 | 3150 | 1970 |

| 2-2×4 | 1960* | 1230* |

| 2-2×6 | 3080 | 1925 |

| 2-2×8 | 4060* | 2540 |

| 2-2×10 | 5180* | 3240 |

| 2-2×12 | 6300* | 3940 |

| 3×6 | 2570* | 1600 |

| 3×8 | 3380* | 2115 |

| 3×10 | 4320* | 2700 |

| 3×12 | 5250* | 3280 |

| 2–3×6 | 5130* | 3210* |

| 2–3×8 | 6760* | 4230* |

| 2–3×10 | 8640* | 5400* |

| 2–3×12 | 10,500* | 6560* |

| 3–2×6 | 4620* | 2890* |

| 3–2×8 | 6090* | 3805* |

| 3–2×10 | 7770* | 4860* |

| 3–2×12 | 9450* | 5905* |

| 4–2×8 | 8120* | 5080* |

| 4–2×10 | 10,360* | 6480* |

| 4–2×12 | 12,600* | 7880* |

| 4×4 | 2290* | 1430* |

| 4×6 | 3590* | 2250* |

| 4×8 | 4740* | 2950* |

| 4×10 | 6040* | 3780* |

| 4×12 | 7350* | 4590* |

| 6×6 | 5650* | 3530* |

| 6×8 | 7700* | 4815* |

| 6×10 | 9750* | 6100* |

| 6×12 | 11,800* | 7380* |

| 8×6 | 7700* | 4810* |

| 8×8 | 10500* | 8560* |

| 8×10 | 13,300* | 8310* |

| 8×12 | 61,100* | 10,060* |

Structural Notes:

1) For one or two joists side by side, use 10dx1 1/2” nails from each side. For 3 Joists side by side, use 16dx3 1/4” sinker nails fron one side and 10dx1 1/2” nails from opposite side. For 4 Joists, used 16d sinker nails from each side.

2) Use hanger capacity or shear capacity whichever is less. Joist Shear capacity shown * exceeds hanger capacity. For these joists use hanger capacity.

3) All design conforms to FBC 2014, IBC/IRC 2015/2012 and NDS 2012.

4) Structural steel shall conform to ASTM A36, yield strength 36000 psi.

5) All welding shall be minimum 3/16˝ with E70 electrodes and shall conform to latest AISC/AWS codes. All welds shall be fillet welds.

6) All nail values in wood conform to latest Edition of NDS for Southern Pine, G=0.55. Values for other species shall be adjusted as per NDS. This applies also to shear values of joists.

7) Steel stress is not increased by 33%.

8) Provide plywood shims to close the gap between joist and steel hangers to prevent bending if necessary.

9) All products are painted Royal Blue for easy identification