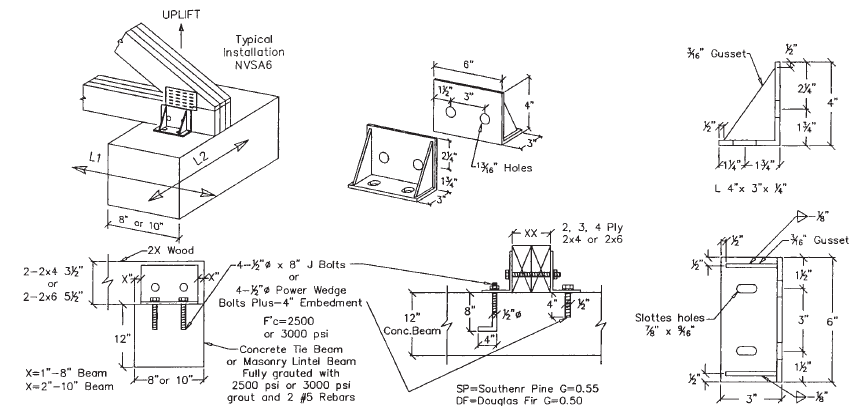

Uplift Truss Connector NVSA6

Wood to Concrete or Concrete Masonry

|

Wood

|

PLYS

|

XX

(IN) |

Allow Uplift Loads (lbs) f’c=2.5 ksi or 3 ksi Bolts 1/2”Ø x 8” or 1/2” Wedge Bolts Plus |

|||

| 8” Concrete Beam |

10” Concrete Beam

|

|||||

|

SP

|

DF

|

Sp

|

DF

|

|||

|

2×4

|

2

|

3

|

2478

|

2184 | 2478 | 2184 |

|

3

|

4 1/2

|

3313 | 3037 | 3313 | 3037 | |

|

4

|

6

|

3737 | 3537 | 3737 | 3524 | |

| 2X6 or Larger |

2 | 3 | 3525 | 3108 | 4248 | 3744 |

| 3 | 4 1/2 | 4714 | 4321 | 5680 | 5206 | |

| 4 | 6 | 5317 | 5015 | 6406 | 6042 | |

| 5516* | 5516* | |||||

* For 1/2” wedge bolts

|

Concrete Beam

|

Allowable Lateral Loads (lbs) L1 2, 3, 4 Plies, SP or DF |

|||

| 1/2” Ø wedge bolts |

1/2” Ø J bolts

|

|||

|

F’C 2.5

|

F’C 3.0

|

F’C 2.5

|

F’C 3.0

|

|

|

8”

|

5461

|

5526 | 6000 | 7200 |

|

10”

|

6750 | 6830 | 6000 | 7200 |

| Allowable Lateral Loads (lbs) L2 2, 3, 4 Plies, SP or DF Beams 8” & 10” |

|||

| 1/2” Ø wedge bolts |

1/2” Ø J bolts

|

||

|

FC 2.5

|

FC 3.0

|

FC 2.5

|

FC 3.0

|

|

7100

|

7185 | 6000 | 7200 |

Structural Notes:

1) Design conforms to FBC 2014. IBC/IRC 2015/2012 and NDS 2012.

2) 1/4” and 3/16˝ thick Structural steel shall conform to ASTM A36, yield strength 36000 psi.,

58000 PSI Tensile Strength. Load Value shown are based on Steel Stress without 33% increase.

3) All welding shall be minimum 1/8˝ with E70 electrodes and shall conform to latest AISC/AWS codes.

All contact areas shall be fully fillet welded.

4) All 3/4” diameter bolts through wood shall be per ANSI/ASME Standard B18.2.1 or ASTM A307.

5) All Power Fasteners wedge bolt plus anchors shall be per Power Fasteners Catalog. Minimum anchor

embedment shall be 4”. Minimum normal weight concrete shall be 2500 psi. Anchor diameter is 1/2”.

Bolt values are with a factor of Safety of 4.

6) 1/2”Ø x 8” anchor bolts Shall Conform to ASTM A307 or A36.

7) Concrete masonry Shall be ASTMC90, F’m = 1500 psi or greater.

8) Lateral loads combined with uplift loads, shall satisfy the following equation:

![]()

9) Uplift and Lateral values shown are reduced for bolt spacing, edge and end distances.

Uplift loads shall not exceed Truss chord capacity.

10) Lateral values are controlled by compression perpendicular to grain of 565 psi for Southern Pine and 625 psi for

Douglas Fir per NDS. For other species, contact Engineer for values.

11) All products are painted Royal Blue for easy identification.

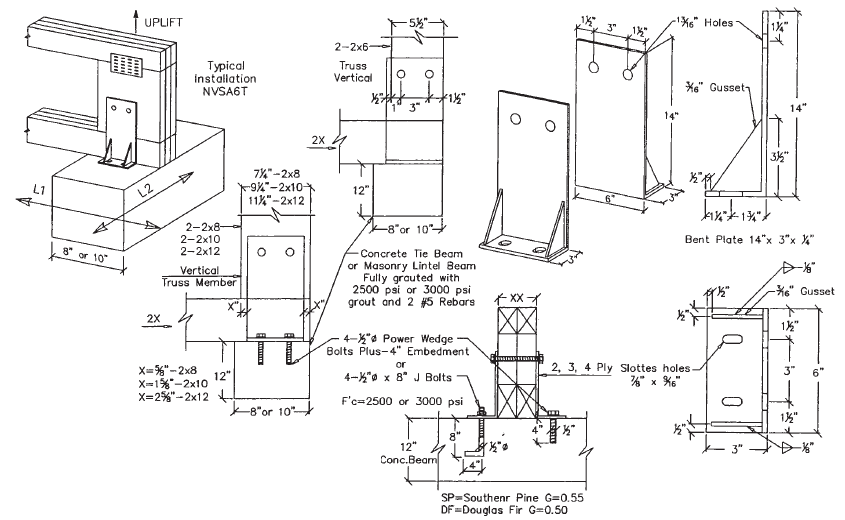

|

Allow L1 (lbs) for Vertical Truss

Member Size & 1/2” Wedge or 1/2” J Bolts |

|||||||

| PLY | Wood | 2 X 6 | 2 X 8 |

2 X 10

2 X 12 |

|||

| F’C 2.5 | F’C 3.0 |

F’C 2.5

|

F’C 3.0

|

F’C 2.5

|

F’C 3.0

|

||

| 2 |

SP

|

3186

|

3186

|

3611

|

3611 | 4248 | 4248 |

| DF | 2808 |

2808

|

3182 | 3182 | 3744 | 3744 | |

| 3 |

SP

|

3857

|

3903

|

4828 | 4828 | 5680 | 5680 |

| DF | 3857 | 3903 | 4425 | 4425 | 5206 | 5206 | |

| 4 |

SP

|

3857 | 3903 | 4908 | 4967 | 6398 6000* |

6406 |

| DF | 3857 | 3903 | 4908 | 4967 | 6042 | 6042 | |

|

WOOD

|

Allowable Lateral Loads (lbs) L1 2, 3, 4 Plies, SP or DF |

|||

| 1/2” Ø wedge bolts |

1/2” Ø J bolts

|

|||

|

F’C 2.5

|

F’C 3.0

|

F’C 2.5

|

F’C 3.0

|

|

|

SP

|

5516

|

6306 | 7792 | 7792 |

|

DF

|

5516 | 6306 | 7792 | 7792 |

| Allowable Lateral Loads (lbs) L2 2, 3, 4 Plies, SP or DF Beams 8” & 10” |

|||

| 1/2” Ø wedge bolts |

1/2” Ø J bolts

|

||

|

FC 2.5

|

FC 3.0

|

FC 2.5

|

FC 3.0

|

|

7100

|

7185 | 6000 | 7200 |

Structural Notes:

1) Design conforms to FBC 2014. IBC/IRC 2015/2012 and NDS 2012.

2) 1/4” and 3/16˝ thick Structural steel shall conform to ASTM A36, yield strength 36000 psi., 58000 PSI Tensile Strength. Load Value shown are based on Steel Stress without 33% increase.

3) All welding shall be minimum 1/8˝ with E70 electrodes and shall conform to latest AISC/AWS codes. All contact areas shall be fully fillet welded.

4) All 3/4” diameter bolts through wood shall be per ANSI/ASME Standard B18.2.1 or ASTM A307.

5) All Power Fasteners wedge bolt plus anchors shall be per Power Fasteners Catalog. Minimum anchor embedment shall be 4”. Minimum normal weight concrete shall be 2500 psi. Anchor diameter is 1/2”. Bolt values are with a factor of Safety of 4.

6) 1/2”Ø x 8” anchor bolts Shall Conform to ASTM A307 or A36.

7) Concrete masonry Shall be ASTMC90, F’m = 1500 psi or greater.

8) Lateral loads combined with uplift loads, shall satisfy the following equation:

![]() 9) Uplift and Lateral values shown are reduced for bolt spacing, edge and end distances. Uplift loads shall not exceed Truss chord capacity.

9) Uplift and Lateral values shown are reduced for bolt spacing, edge and end distances. Uplift loads shall not exceed Truss chord capacity.

10) Lateral values are controlled by compression perpendicular to grain of 565 psi for Southern Pine and 625 psi for Douglas Fir per NDS. For other species, contact Engineer for values.

11) All products are painted Royal Blue for easy identification